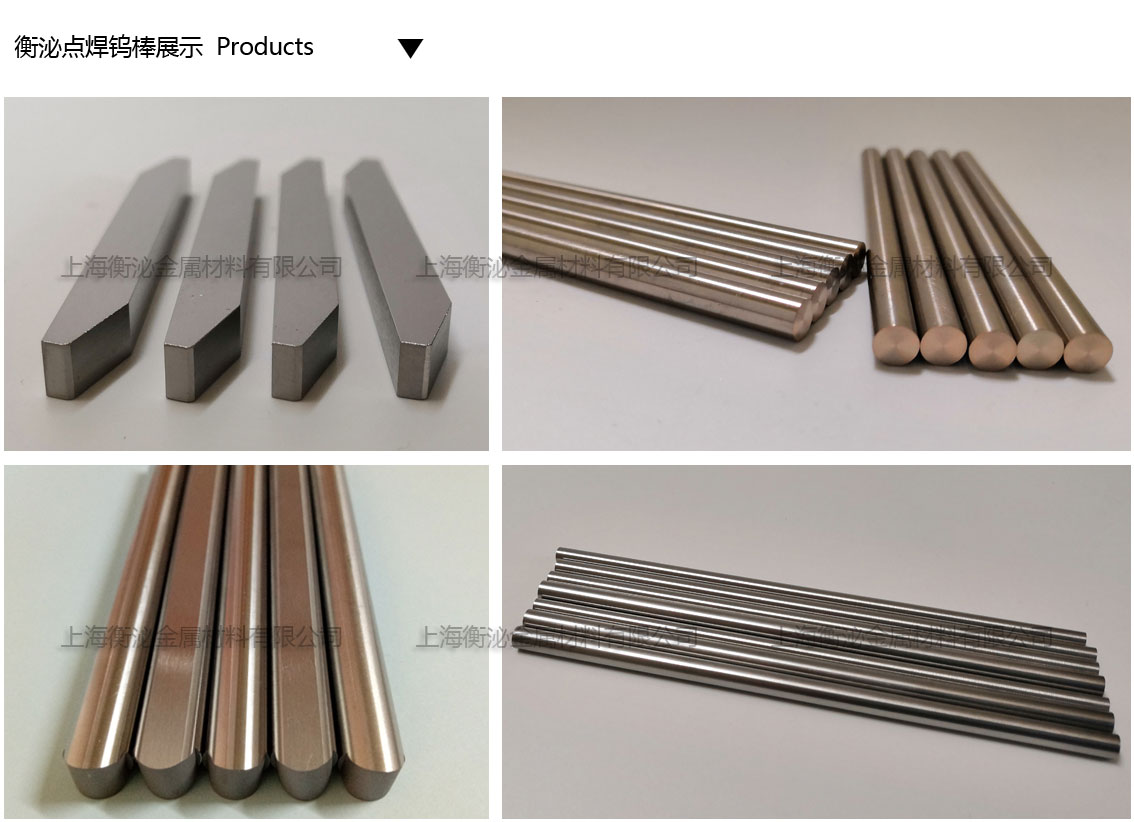

Spot welding tungsten bar

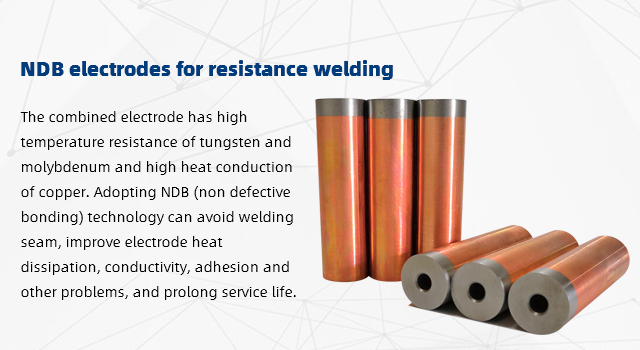

Spot welding tungsten barCombined with many years of experience in the production and processing of resistance welding electrodes, the site of resistance welding can be understood, and the improved design scheme can be provided based on the actual situation of customers.

Each of our electrodes has been densified, with relatively high density and uniform internal structure, which can maintain constant resistance and stable conductivity.

Using the special formula materials for resistance welding, the raw materials with stable quality, giving full play to the physical characteristics of high melting point of tungsten, adding rare earth elements, further optimizing the high temperature stability, creep resistance, high hardness, impact resistance, not easy to deform, no false welding, and solid solder joints;

Specification and parameter table of spot welding tungsten bar:

Name | purity | Density | diameter | tolerance | length |

g/cm3 | mm | mm | mm | ||

Pure tungsten | 99.98% | ≥19.25 | 3.0-30mm | ±0.01mm | ≤200mm |

High purity tungsten | 99.99% | ≥19.25 | 3.0-30mm | ±0.01mm | ≤200mm |

Lanthanum tungsten | 98% | ≥18.8 | 3.0-30mm | ±0.01mm | ≤200mm |

Precision machining service of spot welding tungsten molybdenum electrode:

We can process tungsten, molybdenum and Back cast electrode ( &copper tungsten electrode&copper molybdenum electrode) for resistance welding according to customers' drawings or samples. With the company's advantages in the processing of refractory metal industry, the products are mainly used in the field of precision resistance welding, customized and standard electrodes can be produced and processed. In order to serve you more effectively, please contact us to prepare the following information before contacting us:

1.Materials of parts to be welded

2.Welding current parameters

3.Electrode drawing or physical sample

4.Water cooling design status

5.For problems encountered at present, send the drawings to : sales@sh-tungsten.com or call 021-59241040