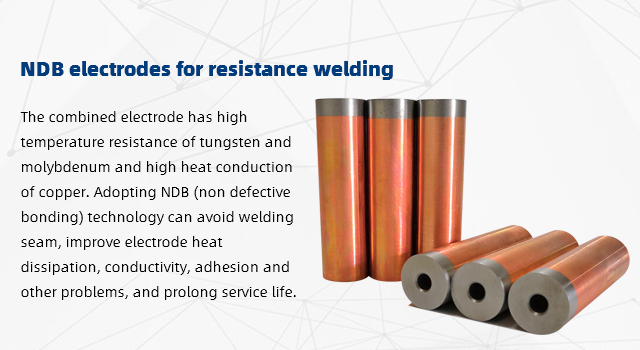

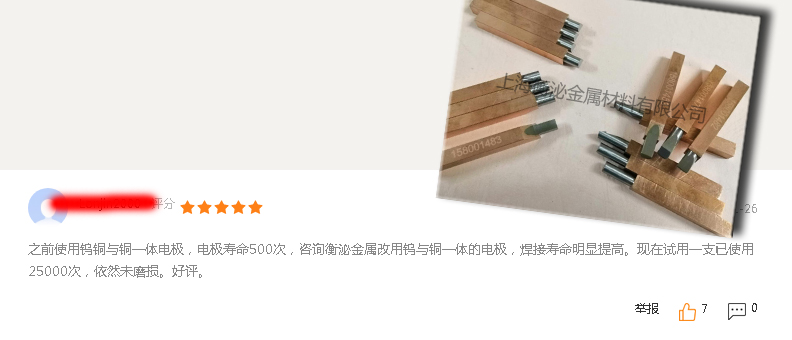

Hengmi's customer, a leading global auto parts manufacturer, first purchased and tested the non defective bonding (no defect welding) of the resistance welding Back-cast Tungsten+Cu electrodes supplied by hengmi metal. As a result, the service life of the Back-cast Tungsten+Cu electrodes is longer than that of the customer's imported tungsten copper inlaid electrode due to the seamless connection between the lanthanum tungsten (wl-20) and copper.

It is understood that the customer mainly uses welding electrode to weld the automobile motor, and the copper or copper alloy sheet is welded with the lead wire. The average service life of the former welding electrode is about 500 times.

Recommended by our product engineer, customers sample Back-cast Tungsten+Cu electrodes. The sample effect is remarkable: at the welding speed of about 120 times / min, the Back-cast Tungsten+Cu electrodes supplied by hengmi production is still not worn after 25000 times of welding, and the final welding life is more than 50000 times, and the welding life is extended by more than 50 times, which is highly praised by customers.

The Back-cast Tungsten+Cu electrodes (also known as resistance welding mosaic electrode, copper inlaid tungsten electrode, etc.) produced by Hengmi metal is composed of pure tungsten, pure molybdenum and its alloy, chromium zirconium copper and oxygen free copper. In the vacuum environment, the integrated connection has stable conductivity and heat dissipation. The end of the electrode can be cooled continuously, reducing the heat load of the end electrode head, thus increasing the service life of the electrode and improving the production efficiency.

If you want to know more, please click the resistance welding electrode page or call us 021-59241040